One wrong kitchen utensil can silently destroy your most expensive pans without you ever realizing it. Many people invest in premium nonstick cookware expecting it to last for years, yet find themselves replacing skillets and saucepans within months because of surface scratches, coating peel, discoloration, or heat stress fractures. The irony is, most of the time the damage doesn’t come from the cookware at all it comes from the spoon stirring inside it. Wooden spoons have stood the test of time across generations for a reason: they are gentle yet strong, simple yet effective, sustainable yet stylish, and among the only traditional kitchen tools that complement nonstick technology instead of competing against it.

Introduction

Nonstick cookware has become a staple in modern kitchens, prized for its smooth, low-friction surface that prevents food from clinging, reduces the need for oils, simplifies flipping or sautéing, and cuts cleaning time dramatically. However, what most people don’t understand is that nonstick pans (whether PTFE/Teflon-based, ceramic-coated, or hard-anodized sealed) are engineered to be slick, not tough. Their longevity depends almost entirely on how the surface is treated during everyday cooking and utensil choice plays a massive role. Hard, sharp, or melting utensils gradually create micro-abrasions that evolve into deep grooves, weakening the coating’s integrity, making it bubble or chip, and eventually shortening the lifespan of your cookware. Wooden spoons, because of their natural molecular and physical properties, remain one of the safest and most intelligent utensil choices for protecting nonstick coatings long-term.

1. Wood vs Nonstick Coatings — Why They Work So Well Together

木 or hardwood cooking utensils interact differently with nonstick surfaces compared to metal or synthetic tools. When a nonstick pan is manufactured, it receives a layer of PTFE or ceramic seal that is sprayed, baked, or chemically bonded to the pan body. These layers must remain intact to preserve prevention of sticking. Wood has a lower hardness level compared to coated aluminum and stainless steel materials, which means it glides without digging. Unlike metal, which is much harder than the pan coating, wood cannot physically carve permanent scars into PTFE or ceramic. At the same time, unlike nylon or plastic, wood doesn’t melt and bond with the surface under heat. It manages to be both soft and heat-durable at the same time a rare combination that makes it part of the elite utensil category suitable for nonstick-safe cooking.

2. Wooden Spoons Prevent Scratches

The Danger of Metal Scratching

Metal spoons or spatulas are structurally rigid, meaning under pressure or slight tilt, they generate sharp contact points that scrape the bonded PTFE or ceramic coating. Most nonstick damage begins as micro-scratches — miniature surface abrasions so small that the human eye often doesn’t catch them in the early stages. But these scratches accumulate each time the pan is stirred, whisked, or scraped, especially when combined with ingredients like salt, sugar crystals, or high-heat searing. When a nonstick surface becomes grooved, it loses its low-friction advantage, making food stick more and forcing users to scrub aggressively, further worsening the damage. Over time, the coating begins chipping away, exposing the pan base, which can lead to uneven heating and potential ingestion of coating flakes.

Why Wood Cannot Scratch the Same Way

Wooden spoons are polished smooth without microscopic sharp edges. The fibrous grain structure distributes force across a wide surface area rather than a single point, preventing gouges. Wood’s Janka hardness is significantly lower than metals used in kitchen tools, which makes it “surface-blind” when stirred inside a nonstick pan — it literally can’t scratch the coating the same way a soft chalk stick can’t scratch marble. Even when pressed against the pan edges, wood compresses slightly instead of cutting in. This forgiving pressure behavior means you can scrape sauces, eggs, rice, curry paste, and thick reductions with confidence, without producing surface trauma.

Scratch Example Visuals

3. Wooden Spoons Do Not Conduct Heat

One of the most overlooked issues in cookware safety is heat conduction. Metal spoons absorb pan heat almost instantly and remain dangerously hot for minutes after being removed. Silicone and nylon resist melting to a point, but their tips and stems still absorb residual heat through conduction or steam exposure. Wood behaves entirely differently. Wood’s porous, cellular composition traps air in its fibers, which makes it naturally resistant to temperature transfer. When you rest a wooden spoon on the edge of a pan or leave it inside a simmering pot for long stirring, you won’t burn your hand when grabbing it again. More importantly, the thermal insulation protects nonstick coatings from sudden temperature spikes caused by super-heated utensil contact. This matters greatly in slow-cooking preparations like creamy pasta sauces, risotto, béchamel, caramel, custards, and tempered chocolate, where pans are kept warm for long durations. Wood ensures consistency by letting you stir without creating artificial hot spots or thermally stressing the coating.

4. Wood Is Chemically Neutral

Some utensils, especially metal, sometimes interact chemically with acid-rich ingredients under heat, triggering ion exchange or accelerated corrosion, especially in cheaper pans. In nonstick cookware, chemical exposure paired with physical abrasion speeds up coating separation from the pan body, causing bubbles or peeling. Wood avoids this risk entirely. Hardwood spoons do not contain reactive compounds that degrade PTFE, ceramic, or anodized seals. There is no risk of acidic tomato, vinegar, citrus, or salt-heavy cooking mixtures reacting with the spoon and transferring microscopic compounds into the coating layer. Because wood does not corrode, oxidize, or release chemical ions, it preserves the original pan surface environment, protecting both the food flavor profile and cookware integrity long-term.

5. No Microplastic Shedding Into Food

Plastic, nylon, and even silicone utensils slowly degrade over time. Many brands soften, tear, or erode microscopically when exposed to oils, boiling liquids, or high heat. These symptoms mean there is a real chance micro-plastics or synthetic fragments are released into hot dishes during stirring, especially in fat-based cooking like butter sauces, ghee, coconut milk curries, ramen broths, cheese melts, or reductions. Wood doesn’t have that problem. Wooden spoons are completely free from petroleum polymers, so even as they age naturally, they do not crumble into toxic micro-fragments. Instead of shedding, wood simply loses moisture, which can be restored through oil seasoning. This makes wood both a safer and more environmentally friendly choice for long-term cooking.

6. Natural Anti-Bacterial Properties

Hardwoods like olive, beech, maple, acacia and teak contain natural resins and phenolic compounds that make it difficult for bacteria to thrive long term. Even if bacteria enters the tiny pores of a wooden spoon, the wood fiber pulls moisture away from microbes, accelerating dehydration, which prevents growth and survival. Unlike plastic, where bacteria remains sitting on the surface, wooden spoons dry internally much faster. This natural evaporation advantage has actually been studied in food safety and is one of the reasons wooden tools are still popular in professional kitchens dealing with long stirring tasks. That said, wood must still be cleaned properly but when cleaned correctly, the bacterial survival rate is significantly lower compared to synthetic tools.

7. Lightweight Ergonomics

Stirring can be physically demanding, especially for dishes that require constant motion. Risotto takes 18–25 minutes of continuous stirring. Thick curry pastes require muscular rotation. Melted jaggery, caramel, or cheese can become heavy to lift repeatedly. Wooden spoons are naturally light yet strong, which significantly reduces wrist fatigue compared to metal alternatives. Wood also doesn’t get slippery when coated with oil or water, giving you better control and stability in motion. This controlled friction makes stirring feel more natural, precise, and less physically taxing in the long run.

8. Gentle Scraping Ability

Many websites mention wood is “good for scraping,” but what they fail to explain is why it matters. When deglazing a pan or loosening sticky residues like eggs or sauces, you want a tool that offers enough friction to pull food away, but not enough hardness to scar the surface. Wood hits that sweet spot perfectly. The rounded, smooth edge lets you scrape, fold, or stir thick foods without losing the grip advantage you’d get with slippery silicone. This makes wood superior for pan-based heat emulsification.

9. Longevity + Restorability

A wooden spoon can last 10 years or more if maintained. Unlike silicone that tears, or nylon that melts, wood can be sanded down when rough and resealed using oils, making it look new again. This restorable aging is one of wood’s biggest advantages, especially for cookware investment protection.

10. Noise-Free Cooking Experience

Scraping metal inside a pan produces unwanted noise, vibration stress, and abrasion. Wood prevents that completely, offering a calmer, quieter cooking environment without coating stress.

11. Aesthetic Value

Wooden spoons double as both functional tools and kitchen décor. Their natural organic look enhances visuals for creators, adds warmth to kitchen setups, and remains timeless.

12. Best Wood Types for Nonstick

Teak resists cracks, maple polishes ultra-smooth, acacia handles moisture, olive is resin-rich, and bamboo is light and strong. These woods remain the best choices for nonstick care.

13. Care & Maintenance

Always hand wash, dry immediately, air-dry upright, and oil every 3–4 weeks using mineral, coconut or olive oil. Avoid soaking to prevent cracks. Wood needs love, not soaking.

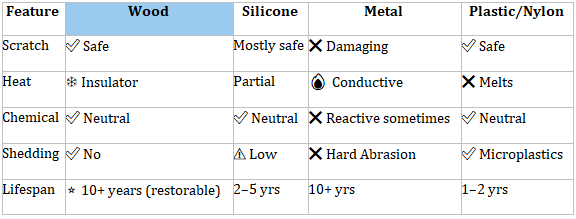

14. Wood vs Utensil Comparison (Big Paragraph Table + Commentary)

Conclusion

The benefits of using wooden spoons for nonstick cookware are rooted in real material behavior, safety science, long-term durability, coating protection, thermal insulation and environmental sustainability. If you want cookware that lasts longer, food that stays cleaner, and utensils that remain safe without toxin shedding, wooden spoons stand ahead of metal and synthetic alternatives. They are forgiving on pan coatings, remain stable at high temperatures, offer superior scraping control, reduce coating wear, and can last for a decade or more when maintained properly. Wood may be traditional, but its benefits are timeless proving that the smartest kitchen upgrades aren’t always the most modern, but the most compatible.